25+ YEARS EXPERIENCE

There are more than 100+ products to choose from to meet your every need.

Mô tả sản phẩm

Applications

Hydraulic turbines are suitable for various industrial applications:

Hydrogenation systems and coolers: The fluid from reaction nozzles to coolers can directly enter the turbine recovery unit.

Gas processing: Used to remove excess liquid, such as wash oil layers, where hydraulic turbines can recover energy.

Chemical production: In synthetic ammonia, CO₂, or ethylene evaporation systems, hydraulic turbines can recover energy from chemical cleaning wastewater.

Reverse osmosis and absorption processes: Hydraulic turbines are ideal for recovering energy from high-pressure reverse osmosis systems.

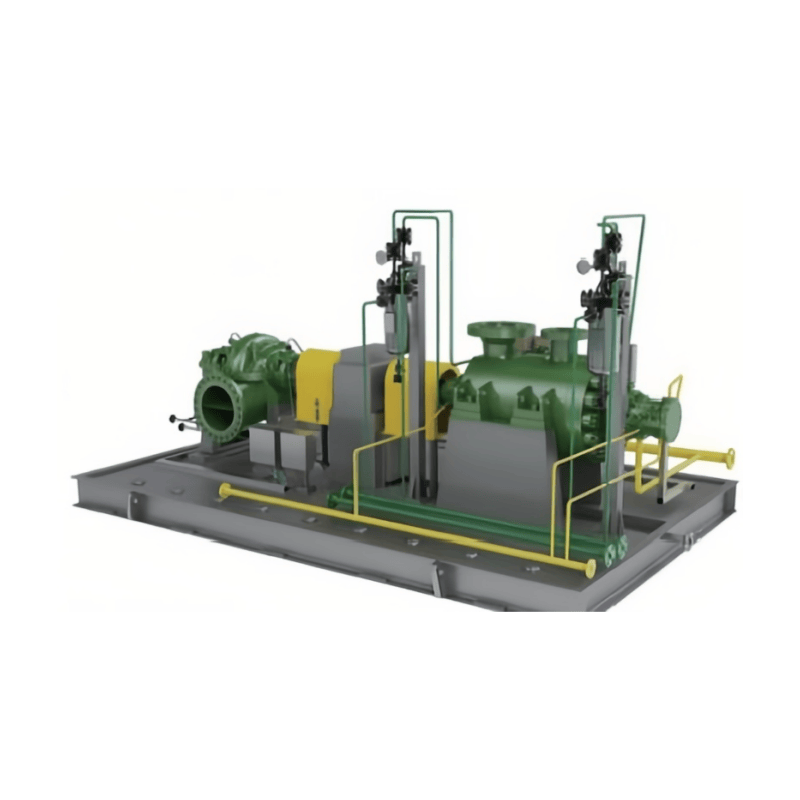

Hydraulic Turbine Unit Configurations

The unit configuration must align with the process flow for economic and operational efficiency. Recommended configurations

include:

Hydraulic Turbine Classifications

TSZE(OH2) Type Hydraulic Turbine

Horizontal, single-stage, cantilever design compliant with API 610 12th Edition.

Centerline-supported, suitable for a wide temperature range.

High-pressure design (up to 110 MPa) with heavy-duty, large-diameter bearings.

Axial force balanced via pressure balance holes; residual forces handled by thrust bearings.

Bearings configured per API 610: angular contact (dual tapered roller bearings) combined with cylindrical roller bearings for radial/axial load support.

Technical Parameters

Flow rate: Up to 2000 m³/h

Head: Up to 150m

Max design pressure: 11 MPa

Temperature range: -60°C to 450°C

A hydraulic turbine converts the pressure energy of liquid fluid into mechanical energy, recovering energy from high-pressure liquids in industrial processes. This method significantly reduces energy waste, offering an eco-friendly, low-carbon solution. The working principle involves high-pressure fluid driving the turbine’s impeller, which rotates the shaft to transmit mechanical energy for reuse.

ƯU ĐIỂM CỦA CHÚNG TÔI

Humanistic Care

Humanistic Care Cumulative Data

Cumulative Data Tailored Solutions

Tailored Solutions Sustainable Manufacturing

Sustainable Manufacturing Excellent Technology

Excellent Technology After-sale service

After-sale service